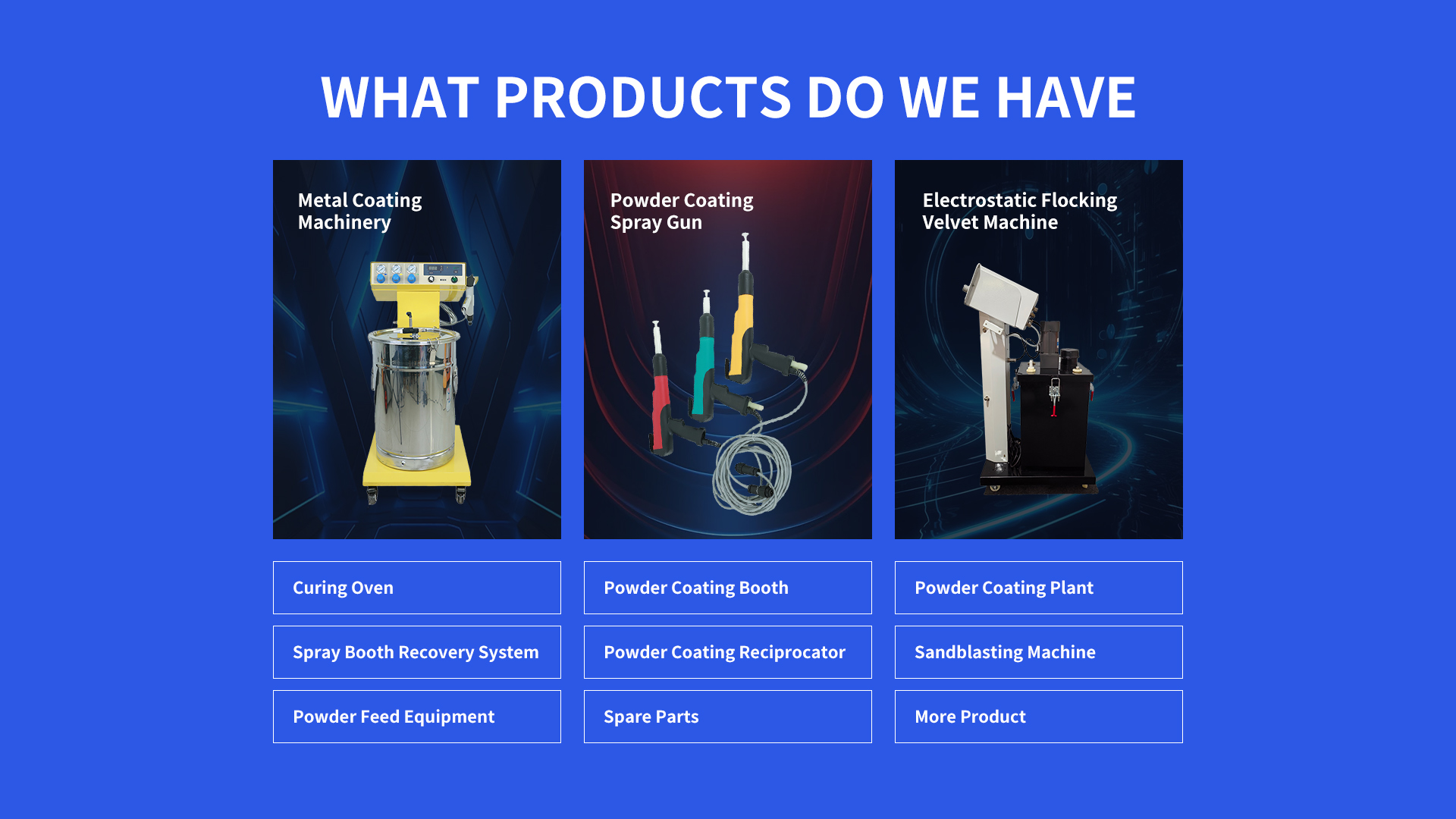

1. Powder Coating Machine Factory Overview and Components

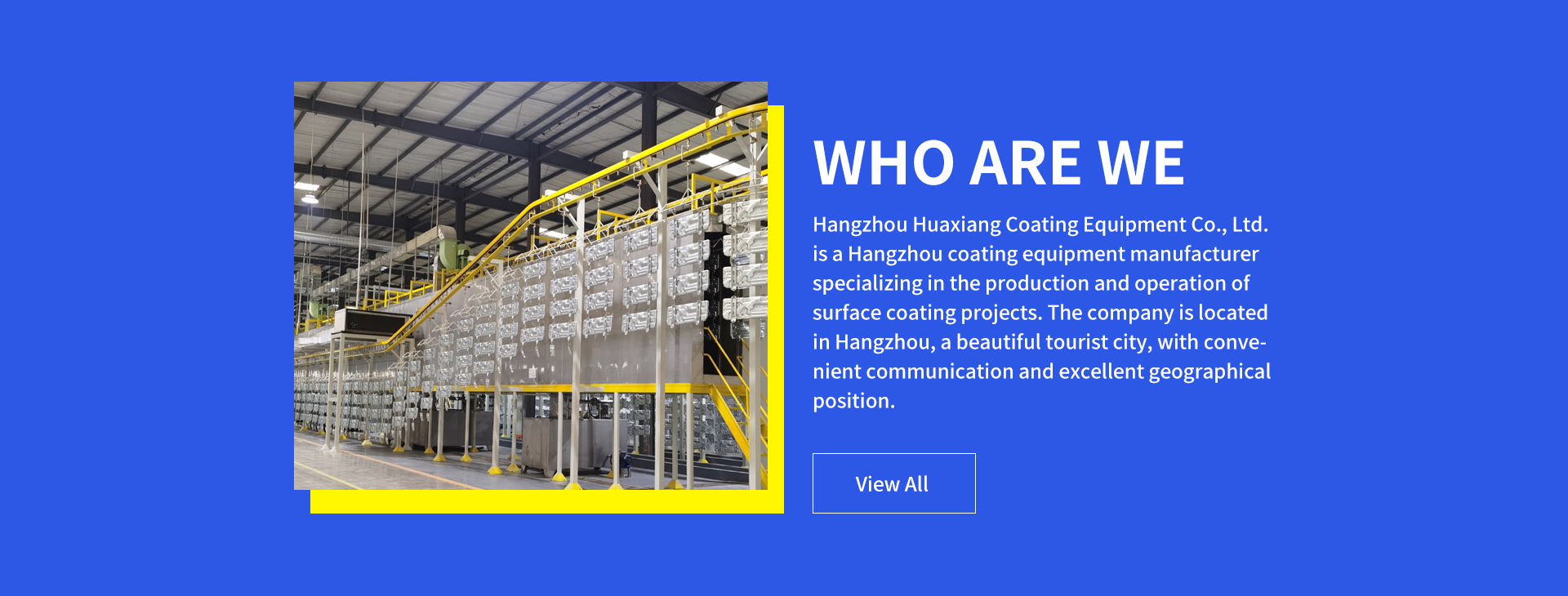

A Powder Coating Machine Factory produces systems that apply and cure powder coatings on industrial products. Key equipment includes electrostatic spray booths, curing ovens, conveyor systems, powder recovery units, and robotic arms. Factories often integrate IoT-enabled controls and modular designs for scalability, ensuring adaptability to diverse production needs.

2. Applications of Powder Coating Machine Factory Systems

These systems are used in automotive (chassis, wheels), aerospace (engine parts), appliance manufacturing (refrigerators, ovens), and architectural metalwork. Powder coating machine factory solutions deliver uniform, corrosion-resistant finishes on metals, plastics (with primers), and composites, meeting high durability and aesthetic standards.

3. Pricing of Powder Coating Machine Factory Equipment

Manual systems start at 10,000∗∗,whilefullyautomatedlinescost∗∗100,000–$500,000+. Costs depend on:

Scale: Small booths (8x6 ft) cost 10k–50k; industrial lines (30x15 ft) exceed $200k.

Automation: Robotic arms add 20k–100k.

Energy Efficiency: Heat-recovery ovens reduce long-term energy bills by 25–40%.

4. Proper Operation of Powder Coating Machine Factory Systems

Pre-treat surfaces via sandblasting or chemical cleaning.

Set spray gun voltage (40–100 kV) and airflow (10–30 psi) for even coverage.

Cure parts at 300–450°F for 10–30 minutes.

Clean filters and nozzles daily; inspect conveyor belts weekly.

5. How to Choose Equipment from a Powder Coating Machine Factory

Production Volume: Manual systems suit <100 parts/day; automated lines handle 500+/hour.

Material Compatibility: Ensure compatibility with epoxy, polyester, or hybrid powders.

Certifications: Prioritize CE, UL, or OSHA compliance.

After-Sales Support: Opt for factories offering warranties and technical training.

6. Safety Protocols in Powder Coating Machine Factories

Install explosion-proof ventilation and grounding systems.

Use NIOSH-approved respirators (N95+) and fire-resistant clothing.

Store powders in temperature-controlled areas away from ignition sources.

Conduct monthly inspections of electrical components and emergency stops.

7. Cost-Efficiency of Powder Coating Machine Factory Designs

Automated systems reduce labor costs by 50% and material waste by 90% via high-efficiency recovery (95%+). Modular designs allow upgrades like UV curing modules or IoT integration, extending equipment lifespan to 10–15 years.

8. FAQs About Powder Coating Machine Factory Equipment

Q: What industries benefit most from powder coating machine factories?

A: Automotive, aerospace, and appliance sectors rely on these systems for mass production.

Q: How to minimize powder waste in factory systems?

A: Use cyclone separators and HEPA filters for 95–99% recovery rates.

Q: Can factories customize machines for heat-sensitive materials?

A: Yes—UV-curable powders and low-temperature ovens protect plastics and wood.

Q: Are factory-produced machines energy-efficient?

A: Modern designs with heat recycling cut energy use by 30–40%.

Q: What certifications ensure factory equipment safety?

A: Look for CE, ATEX, or UL marks for compliance with global standards.

This guide equips businesses with critical insights into powder coating machine factory solutions, optimizing performance, safety, and ROI in industrial finishing processes.

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com